From supercritical CO₂ extraction to custom formulation, Valensa helps turn your raw materials into scalable, compliant, and market-ready products.

Nutraceutical Ingredient | Food Ingredient | Cosmetic Ingredient | Functional Food

From supercritical CO₂ extraction to custom formulation, Valensa helps turn your raw materials into scalable, compliant, and market-ready products.

Nutraceutical Ingredient | Food Ingredient | Cosmetic Ingredient | Functional Food

Whether you’re exploring refining an existing process, or scaling to commercial production, Valensa offers complete supercritical CO₂ extraction services tailored to your needs.

Valensa has decades of experience delivering proprietary, science-backed ingredients to market—including saw palmetto and astaxanthin. We’re not just a toll processor—we’re a technical partner.

Science-Driven Extraction & Innovation

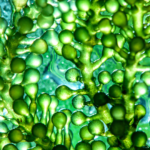

Supercritical CO₂ is ideal for extracting non-polar compounds like lipids and oils from botanicals, algae, seeds, and spices. It’s solvent-free, food-grade, and aligned with global clean-label standards.

Capabilities Include:

Need a finished product? Our network of strategic manufacturing partners allows seamless delivery into commercial formats:

Our manufacturing and quality systems are USP-audited to ensure full compliance with 21 CFR Part 117—covering Current Good Manufacturing Practices (cGMP), Hazard Analysis, and Risk-Based Preventive Controls for Human Food. We also adhere to USP-NF General Chapter <2740> for Manufacturing Practices of Dietary Ingredients, ensuring the highest standards of quality and safety.

Quality & Compliance: Exceeding Industry Standards

Natural Products, Certified Facility

We maintain rigorous quality and regulatory standards across every project—supported by in-house lab testing and recognized certifications.

Valensa has decades of experience delivering proprietary, science-backed ingredients to market—including saw palmetto and astaxanthin. We’re not just a toll processor—we’re a technical partner.

Valensa partners with leading brands to deliver high-quality, science-backed extraction solutions for a variety of industries. From shelf-stable Omega-3 blends to concentrated bioactives, our expertise ensures purity, potency, and performance across diverse applications.

Shelf-Stable Omega-3s for Gummies

Valensa extracted chia seeds to create a great tasting, shelf-stable Omega-3 blend for a top gummy brand sold at a major retailer.

Concentrating Bioactives

Valensa extracted broccoli seeds for a top brand to help them isolate and concentrate bioactive compounds based on their health benefits – without damaging the key nutrients.

Organic ingredient for baby foods

Valensa conducted feasibility studies on extracting a proprietary natural product for specific fatty acids with zero residual solvent that can be used in organic baby foods.

Spice Extracts for Food and Functional Ingredients

Valensa extracted and standardized rosemary extract for a leading food ingredient company and standardized the actives in ginger root for a dietary supplement application.

Microalgae Extraction Excellence

Valensa toll-extracted astaxanthin for a leading Haematococcus grower ensuring standardization and stability for optimal quality.